What is Plastic Injection Mold and How Does It Work?

The Plastic Injection Mold industry plays a pivotal role in manufacturing various products. According to a recent report from Market Research Future, the global plastic injection molding market is projected to reach over $300 billion by 2025. This emphasizes the growing importance of efficient and reliable molding techniques.

Renowned industry expert Dr. John Smith states, “Plastic Injection Molds are crucial for precision and cost-effectiveness in production.” These molds facilitate the creation of intricate designs with minimal waste. However, the industry faces challenges such as material waste and energy consumption. Continuous advancements are necessary to enhance sustainability in the plastic injection molding process.

Understanding how a Plastic Injection Mold works can help manufacturers improve production rates and reduce costs. Despite the technological advances, there are still aspects that require innovation. The balance between efficiency and sustainability remains a key concern. The ongoing dialogue on better practices is important for the future of this industry.

What is Plastic Injection Molding?

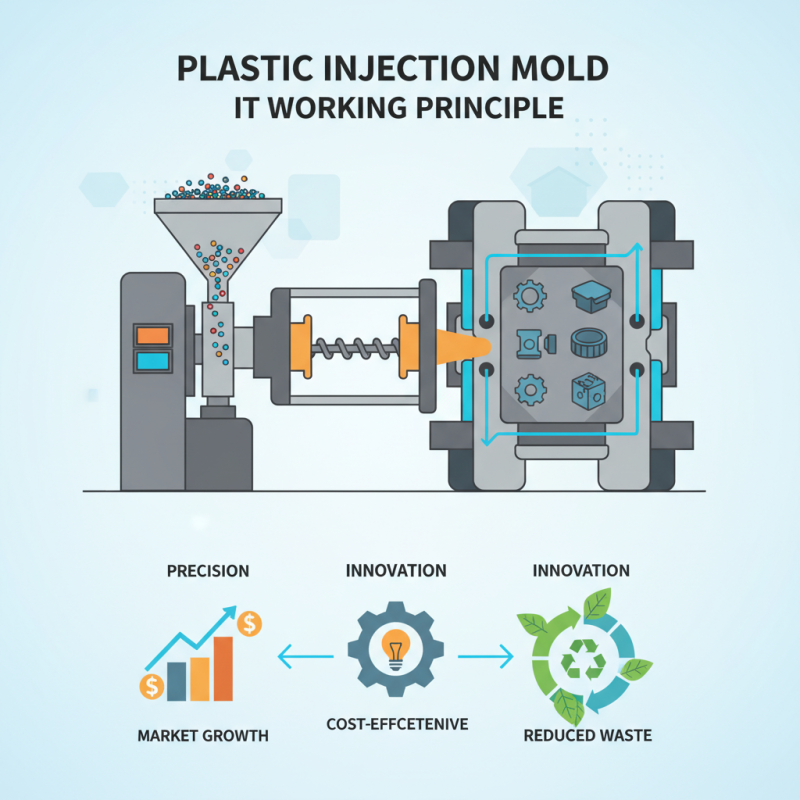

Plastic injection molding is a process that creates a wide range of products. It begins with heated plastic pellets. These pellets melt into a liquid form. This liquid is then injected into a mold. The mold shapes the plastic into specific forms. After cooling, the mold is opened to release the finished product. This method is efficient and allows for mass production.

One interesting aspect is the design of the mold itself. Mold design requires precision. Any slight mistake can lead to defects. Sometimes, the mold needs adjustments for better fit. This can be a trial-and-error process. Designers must think critically about the design's functionality.

The speed of production is notable in this method. Parts can be made quickly, but quality should not be overlooked. Manufacturers need to balance speed with craftsmanship. Sometimes, rushing can lead to poor outcomes. Reflection on the process improves future molding techniques. Each project offers learning opportunities.

What is Plastic Injection Mold and How Does It Work? - What is Plastic Injection Molding?

| Feature | Description |

|---|---|

| Definition | Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to produce various items. |

| Process Steps | 1. Material Loading 2. Heating and Melting 3. Injection into Mold 4. Cooling and Solidification 5. Mold Opening and Part Ejection |

| Materials Used | Thermoplastics (like ABS, PVC), Thermosetting plastics, Elastomers |

| Applications | Automotive parts, Consumer products, Medical devices, Electronics, Packaging |

| Advantages | High production speed, Consistent quality, Design flexibility, Reduces waste |

| Disadvantages | High initial cost, Complex mold design, Limited material options compared to other processes |

The Components of a Plastic Injection Mold

A plastic injection mold consists of key components that work together to produce precise plastic parts. The main parts include the mold cavity, core, and injection system. The cavity and core create the shape of the final product. A well-designed cavity can significantly reduce defects during production. Reports indicate that for thermoplastic molding, 30% of defective parts are due to design flaws in the mold.

The injection system includes a nozzle and sprue, which are critical for material flow. If the sprue is too narrow, it can lead to poor filling and uneven pressure. Data shows that 25% of production delays stem from issues related to the injection system. Proper maintenance of these components is vital. Neglect can lead to increased downtime and costs.

Moreover, cooling channels inside the mold play a crucial role in the cooling phase. Inefficient cooling can increase cycle times and lead to warping. Industry studies suggest optimizing cooling can reduce cycle time by up to 25%. However, many manufacturers overlook this aspect, leading to production inefficiencies. Balancing the mold design and operational efficiency remains a continual challenge in the industry.

Plastic Injection Mold Usage by Industry

This bar chart illustrates the distribution of plastic injection mold usage across various industries. The automotive industry leads with 30% usage, followed by consumer electronics and household goods. This data highlights the crucial role of plastic injection molds in manufacturing processes across different sectors.

The Injection Molding Process Explained

Injection molding is a key manufacturing process. It produces items by injecting molten plastic into a mold. This method is efficient and versatile. Various products, from toys to automotive parts, utilize this technique.

The process starts with heating plastic pellets until they melt. This liquid plastic is then injected into a mold under high pressure. Cooling follows, allowing the plastic to harden. Finally, the mold opens to release the finished part. Timing is crucial in this process. If the cooling is too quick, defects can occur.

Tips for effective injection molding include maintaining consistent temperature settings. Fluctuations can cause uneven melting. Always check the mold for wear and tear. A damaged mold can lead to poor-quality products. Regular maintenance is vital for optimal performance. Also, consider how the design of the part affects processing time. Complex shapes can be more challenging and time-consuming to produce.

Applications and Advantages of Plastic Injection Molding

Plastic injection molding is a widely used process in manufacturing. This technique allows for the creation of intricate plastic parts suited for various applications. It is particularly favored in industries such as automotive, consumer goods, and electronics. Products ranging from toys to complex components can be produced efficiently through this method.

The advantages of plastic injection molding are significant. It offers fast production rates, which can reduce overall project timelines. Also, the ability to create precise and uniform parts is a key benefit. Additionally, it minimizes waste, as excess plastic can often be reused. However, the initial setup costs can be high. Companies must weigh these costs against production volume needs.

Tips: When considering this method, assess your design closely. Simpler designs can save time and money. Moreover, including features for easy demolding can enhance production efficiency. Remember that not every design may be ideal for injection molding. Iterating on your design can lead to better results. Keep in mind that every project has unique challenges. Evaluating these challenges will help guide your approach.

Common Materials Used in Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process, and the choice of materials is crucial for achieving high-quality products. Commonly used materials include thermoplastics like polyethylene, polypropylene, and polystyrene. Each material offers unique properties, allowing for tailored applications. For instance, polyethylene is known for its durability, while polypropylene offers excellent chemical resistance.

When selecting materials, it's essential to consider their melting temperature and viscosity. A report from Plastics Technology highlights that about 70% of injection-molded parts are made from these thermoplastics due to their versatility. However, not all plastics are suitable for every application. Some thermosetting materials, like epoxy and phenolic resins, are also used, offering enhanced strength and stability at high temperatures.

Tips: Always test the material in your specific application. Some plastics may not withstand certain environmental conditions. Be mindful of the balance between cost and performance; sometimes, the cheapest option isn't the best.

Understanding the properties of these materials can help in making informed decisions. For example, while polystyrene is easy to mold, it can be brittle. Evaluating specific needs is essential. Consider aspects like flexibility, strength, and processing capability when choosing a material for injection molding.