How to Choose the Right Foam Packaging for Your Products

In an era where e-commerce continues to experience exponential growth, the significance of effective product protection cannot be overstated. According to a report by Smithers Pira, the global market for protective packaging, including Foam Packaging, is projected to reach $40.4 billion by 2024, driven by the rising demand for efficient shipping solutions. Foam Packaging has emerged as a popular choice among manufacturers due to its lightweight properties and exceptional shock absorption capabilities, which help in reducing transit damages. As businesses strive to enhance customer satisfaction and minimize returns, selecting the right type of Foam Packaging becomes crucial. This blog will guide you through the essential considerations for choosing the ideal Foam Packaging for your products, ensuring optimal protection and efficiency while aligning with industry standards.

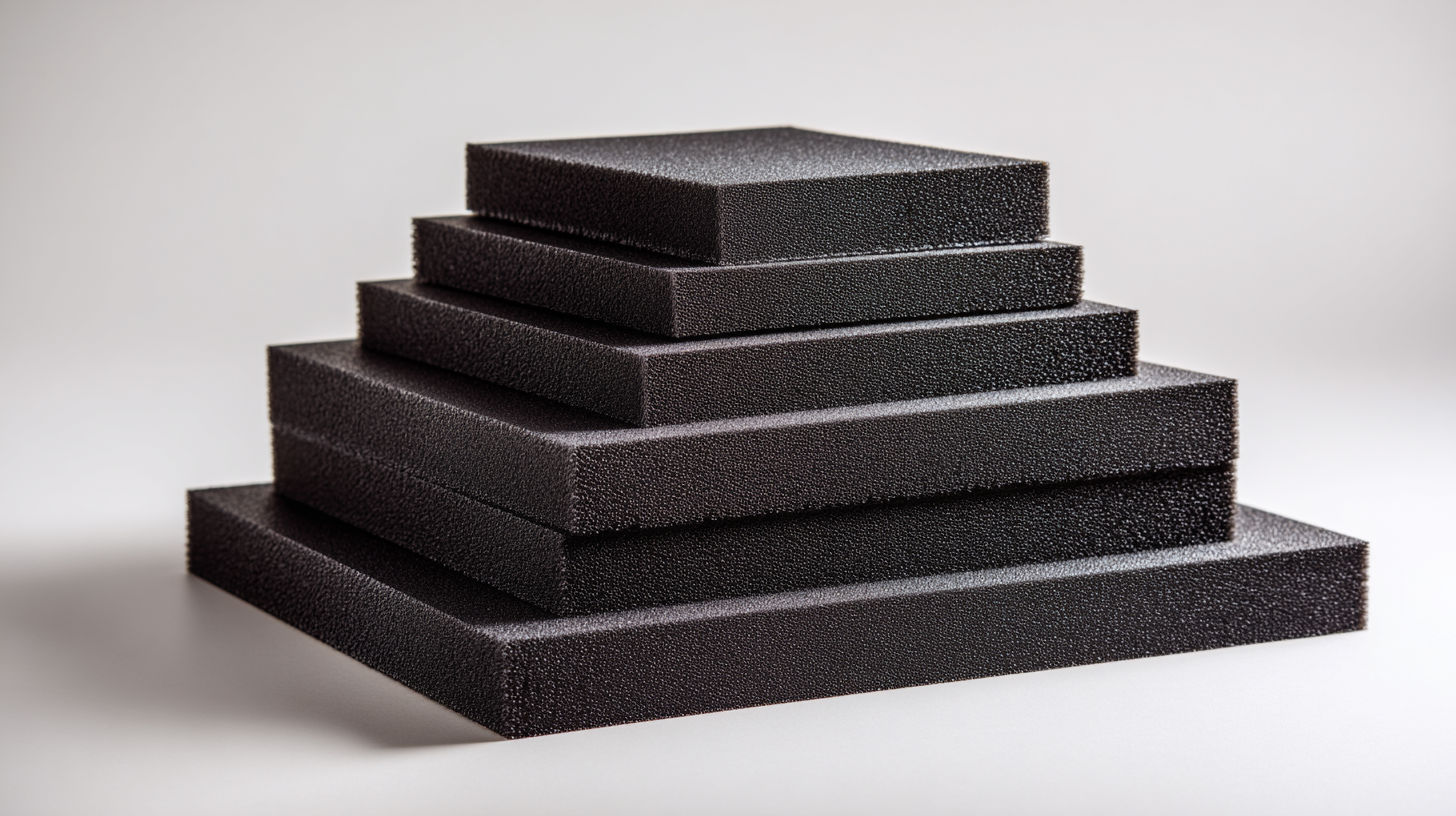

Understanding Different Types of Foam Packaging Materials

When selecting the appropriate foam packaging for your products, it’s essential to understand the various types of foam materials available in the industry. Expanded Polystyrene (EPS) foam, which comprises around 90-95% air, is known for its lightweight and insulating properties. According to a report by Smithers Pira, the global market for EPS packaging is expected to reach $11.4 billion by 2025, demonstrating its popularity due to effective shock absorption and thermal insulation. This makes it an excellent choice for fragile items like electronics or temperature-sensitive goods.

Another widely utilized option is Polyurethane (PU) foam, celebrated for its versatility and durability. PU foam can be molded into intricate shapes, making it ideal for custom packaging solutions. The market for polyurethane foam in packaging is projected to grow significantly, fueled by the increasing demand for high-performance, protective packaging. Based on data from MarketsandMarkets, the global PU foam market is forecasted to reach $55.2 billion by 2026. When considering foam types, understanding these materials’ properties and market trends can significantly impact the reliability and efficiency of your product packaging strategy.

Assessing the Protective Needs of Your Products

When selecting foam packaging, it’s essential to assess the protective needs of your products to ensure they reach their destination safely. Different products have varying levels of fragility; for instance, delicate electronics require cushioning that can absorb shock and prevent movement, while more robust items, like tools, may need less protective layering. Understanding the specific vulnerabilities of your products helps in choosing the right foam density and type, whether it’s polyurethane, polyethylene, or another material.

Additionally, consider the environmental factors your packaging may encounter during transit. Exposure to moisture, temperature fluctuations, or pressure can compromise the integrity of your products. Therefore, foam packaging should not only provide physical protection but also resist these elements. Evaluate the nature of your supply chain and transport methods to select the appropriate foam that aligns with the protective requirements dictated by the environment, ensuring that your products are maintained in optimal condition throughout their journey.

How to Choose the Right Foam Packaging for Your Products

Evaluating Cost-Effectiveness of Foam Packaging Solutions

When selecting foam packaging for your products, evaluating cost-effectiveness is crucial. Foam packaging comes in various types, including polyurethane, polystyrene, and polyethylene, each with different price points and protective qualities. To determine the most economical option, consider not only the upfront costs but also the long-term benefits, such as durability and reusability. Investing in higher-quality foam may reduce the risk of product damage during transit, ultimately saving your business money on returns and replacements.

Moreover, analyze the potential savings in freight costs associated with lightweight foam materials. Product weight can significantly impact shipping expenses, and choosing a lighter foam can lower your overall shipping bills. Additionally, consider the efficiency of packaging space; optimized foam cuts down on wasted space within shipping containers, further decreasing shipping costs. An effective evaluation should incorporate these factors to find a balance between affordability and the level of protection required for your products, ensuring that your investment aligns with your business goals.

Sustainable Options for Eco-Friendly Foam Packaging

When selecting foam packaging for products, the emphasis on sustainability has never been more critical. In recent years, the demand for eco-friendly solutions has surged, with a report by Smithers Pira indicating that the sustainable packaging market is expected to reach $475 billion by 2024. This shift stems from environmental concerns and consumer preferences for greener products. Companies can choose from biodegradable foam materials, such as plant-based foams, which decompose naturally and offer a responsible alternative to traditional petroleum-based foams.

Tips for choosing sustainable foam packaging include evaluating options like recycled content and biodegradable alternatives. Look for packaging suppliers who utilize materials that can break down without leaving harmful residues. It's essential to assess the lifecycle of your packaging materials; selecting options that reduce carbon footprints and to collaborate with manufacturers committed to sustainability could significantly impact your business's environmental footprint.

Moreover, embracing innovative designs that minimize material usage can complement your eco-friendly packaging strategy. Techniques like effective cushioning with thinner profiles not only reduce material waste but also lower shipping costs by optimizing space. By implementing these strategies, businesses can ensure that their packaging choices align with both consumer expectations and environmental responsibilities.

Customizing Foam Packaging for Unique Product Shapes and Sizes

When it comes to protecting your products during shipping and storage, customizing foam packaging is essential, especially for items with unique shapes and sizes. According to a report by Freedonia Group, the demand for foam packaging is expected to grow by 4.8% annually, highlighting its importance in various industries. Tailoring foam inserts to fit your products precisely can minimize movement and damage, thus ensuring that your items reach their destination intact.

**Tip:** Utilize CAD technology to create precise foam packaging designs that conform perfectly to your product outlines. This not only prevents damage but can also reduce material costs by eliminating excess foam.

Moreover, choosing the right density and thickness of foam can significantly affect the protection level. For example, softer foams are ideal for lightweight or fragile items, while denser foams can better support heavier products. A survey by Smithers Pira indicates that companies increasingly prioritize protective packaging solutions, with over 60% considering customized designs to enhance product safety.

**Tip:** Test different foam formulations and designs to find the optimal solution for your specific product needs; conducting drop tests can provide vital insights into the effectiveness of your packaging before full-scale production.

How to Choose the Right Foam Packaging for Your Products - Customizing Foam Packaging for Unique Product Shapes and Sizes

| Product Type | Foam Type | Dimensions (L x W x H) | Weight Capacity | Custom Options |

|---|---|---|---|---|

| Electronics | Polyethylene Foam | 10 x 8 x 2 inches | 5 lbs | Die-cut, Antistatic |

| Glassware | Ethafoam | 12 x 6 x 6 inches | 10 lbs | Cushion Inserts, Custom Shapes |

| Automotive Parts | Polyurethane Foam | 20 x 15 x 10 inches | 30 lbs | Custom Cutouts, Moisture Resistant |

| Industrial Equipment | Cross-linked Polyethylene | 25 x 20 x 15 inches | 50 lbs | Heavy-duty, Custom Colors |

| Medical Devices | Medical-grade Foam | 15 x 10 x 5 inches | 8 lbs | Sterilizable, Custom Sizes |

Related Posts

-

Issues with Traditional Insulated Shipping Solutions Compared to Foam Shipping Coolers

-

Explore China's Top Molded Pulp Innovations: Quality Products for Global Buyers

-

Discover the Power of Chinese Manufacturing with Best Custom Insulated Boxes for Global Buyers

-

How to Choose the Right Insulated Packaging for Your Products

-

Exploring the Advantages of Best Shipping Styrofoam for Your Business

-

Innovative Ways to Use the Best Foam Shipping Cooler for Your Next Adventure